HRC...N

HRC...N

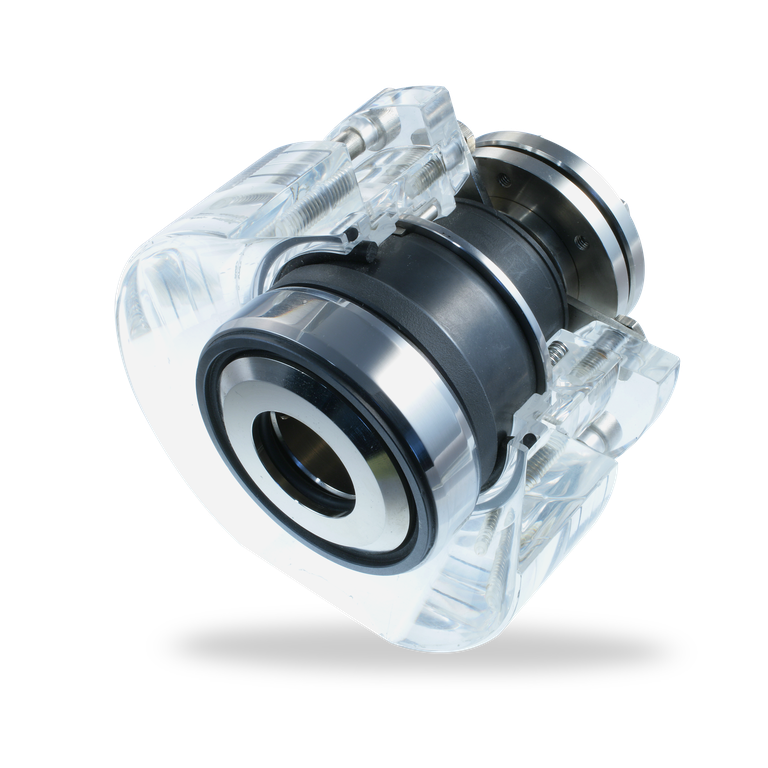

HRC3300NF

With uni-directonal pumping screw. Dual seal remains closed in case of barrier pressure failure and closes in the event of pressure reversal. With guide sleeve (item no. 12). Operation as single seal with quench possible. Encapsulated stationary seat on the product side (bursting protection). Parted seal sleeve for application of highly restistant materials e.g. Hastelloy®.

With uni-directonal pumping screw. Dual seal remains closed in case of barrier pressure failure and closes in the event of pressure reversal. With guide sleeve (item no. 12). Operation as single seal with quench possible. Encapsulated stationary seat on the product side (bursting protection). Parted seal sleeve for application of highly restistant materials e.g. Hastelloy®.

| Item | Part no. to DIN 24250 |

Description |

| 1.1.1 | 472.1 | Seal face |

| 1.1.2 | 474 | Thrust ring |

| 1.1.3 | 477.1 | Spring |

| 1.2 | 475.1 | Seat |

| 2 | 523 | Shaft sleeve |

| 4 | 513 | Insert |

| 8 | 160 | Cover plate |

| 9 | 509 | Spring carrier |

| 12 | Spring protection sleeve | |

| 19 | Plug | |

| 24 | Assembly fixture |

HRC...N

Features

- Cartridge

- Balanced

- Independent of direction of rotation

- Stationary multiple springs

- Spring protection sleeve

- Variant for operation with pressureless quench available (HRC2000N)

- Dual seal with and without pumping screw (HRC3300NF, HRC3300N) available

Advantages

- Insensitive to solids containing media. Solids content 40 % (single seal), 60 % (double seal)

- Springs protected from product and leakage

- Variant with short installation length to meet limited space conditions (HRC1100N)

- Dual seal remains closed in case of barrier pressure failure, self-closing at pressure reversal (HRC3300NF)

- Operation under vacuum without seat locking possible

- No damage of the shaft by dynamically loaded O-Ring

- Insensitive to shaft deflections due to stationary design

Materials

Seal face: Silicon carbide (Q1, Q2)

Seat: Carbon graphite antimony impregnated (A), Silicon carbide (Q1, Q2)

Seat: Carbon graphite antimony impregnated (A), Silicon carbide (Q1, Q2)

Standards and approvals

- DIN 24960 C

Recommended applications

- Chemical industry

- Process industry

- Petrochemical industry

- Mining industry

- Sugar industry

- Dirty, abrasive and solids containing media

- Various chemical processes

- Chemical standard pumps

Product variants

HRC1000N

Single seal

HRC1100N

Same design as HRC1000N, but with a shorter cover plate featuring integral spring and drive pin pockets (Item no. 8). No adapter (Item no. 9). Shaft sleeve (Item no. 2) uncoated. Differs from modular system!

Single seal

HRC1100N

Same design as HRC1000N, but with a shorter cover plate featuring integral spring and drive pin pockets (Item no. 8). No adapter (Item no. 9). Shaft sleeve (Item no. 2) uncoated. Differs from modular system!

HRC2000N

Single seal with pressureless quench for cooling, featuring guide sleeve (Item no. 12) baffle (Item no. 17), adapter (Item no. 15) and lip seal (Item no. 13) on the atmosphere side. Option: Throttle ring for sealing steam quench on the atmosphere side.

Single seal with pressureless quench for cooling, featuring guide sleeve (Item no. 12) baffle (Item no. 17), adapter (Item no. 15) and lip seal (Item no. 13) on the atmosphere side. Option: Throttle ring for sealing steam quench on the atmosphere side.

Similar products

DF-(P)DGS6

- Dry gas seal for multiphase pump applications

- DiamondFace sliding surface technology

- Ideal for applications with Ethane, CO2, and similar media with low vapor margins

- Shrouded rotating ring

- Bi-directional

- Ready-to-fit cartridge unit

- Single, double, tandem, and tandem with intermediate labyrinth available

DF-SA DiamondFace

- Cartridge design

- Single seal

- Balanced

- Integrated pumping device

- Stationary spring loaded unit

- Inserted seal ring

- Rotating mating ring

(DiamondFace coated)

HR

- Single seal

- Balanced

- Independent of direction of rotation

- Multiple springs stationary

- Seat rotating

- Seat arranged directly behind the impeller

- Spring protection sleeve

- Variant with cylindrical spring and acc. EN 12756 (HRZ1) available

- Variant as cartridge with/without guide sleeve for application with/without quench (HR2, HR3)

- Dual seal as cartridge unit (HRKS-D) available