Situation

Darlington Nuclear Generating Station with 16 Sulzer single-stage vertical reheater drain pumps

Darlington Nuclear Generating Station with 16 Sulzer single-stage vertical reheater drain pumps

Large temperature differences and high pressure led to inadequate cooling

SHFV1/42-E1, a new sealing system with API plan 23

Darlington Nuclear Generating Station is located 70 km east of Toronto (Canada). The four unit station is the newest generating station of Ontario Power, performs a total output of 3,512 MW and provides about 20 % of Ontario‘s electricity needs - enough to serve a city of two million people.

16 Sulzer single-stage vertical reheater drain pumps type BJ3X4X11 model TXR are installed. The second stage reheater drains system drains the condensate, and vents any uncondensed steam from the second stage reheater tube bundles and directs these to the steam generator and the HP heater.

The pumps in question were originally equipped with a competitor‘s seal system, operated acc. to API plan 41. High temperature and high pressure caused problems for the seal and its supply system. Because of large temperature differences between the cold cooling medium (lake water) and the hot process medium (demineralized water) an excessive deposit of cooling water sediment occured and the coil of the heat exchanger regularly plugged. Therefore, inadequate cooling was provided which resulted in dry running of the seal faces and ended in seal failure.

These failures occurred up to 10 times a year and caused a loss of efficiency of 4 MW, costing 5,000 CAD per day.

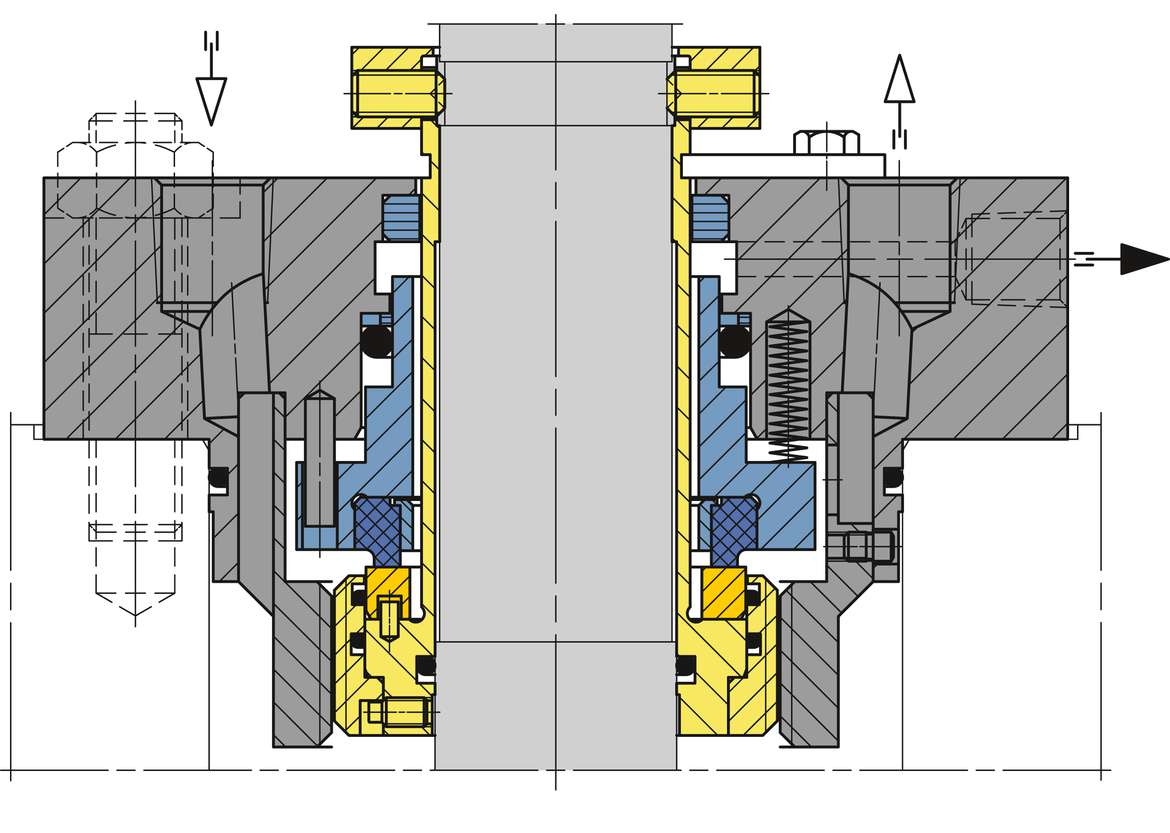

Illustr. 1: SHFV High pressure mechanical seal for boiler circulation pumps. Dual seal in tandem arrangement, with pumping screw

Illustr. 2: Yellow parts = rotating, blue = stationary, gray = housing

EagleBurgmann designed a new sealing system, the SHFV1/42-E1 with API plan 23. This system had to pass through a performance test at the EagleBurgmann facilities in Wolfratshausen, Germany. The test was arranged with the original equipment and under operation conditions of Darlington Nuclear. All tests have been performed successfully without any problems.

The first SHFV1/42-E1 with API plan 23 was installed in 2007. Another 15 sealing systems follwed in 2008. Since start-up the seals show excellent performance and run without any problems.

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Frequent starts and stops are a severe test for gas-lubricated compressor seals. Installed in an Argentinean combined cycle power plant is an EagleBurgmann supply system that provides a continuous gas flow rate for the seals and adapts it to changing conditions. Since then, the operational reliability of the compressors has increased significantly.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.