Situation

Modifications of several units in a German refinery as part of the TMC (total monomer concept) process

NMB magnetic couplings as solution for extreme operating conditions

Modifications of several units in a German refinery as part of the TMC (total monomer concept) process

High pressure, extremely high torque, high power rating and highly flammable medium

Magnetic coupling by EagleBurgmann Nova Magnetics

As part of the TMC (total monomer concept) process, modifications were made to an ethylene cracker and a new olefin conversion unit (OCU) was built to boost ethylene and propylene productivity at a German refinery. During the course of this project, EagleBurgmann was awarded a contract to provide hermetic sealing for four multistage vertical can pumps. The pumps are used to circulate highly flammable liquid hydrocarbons (C2 and C4).

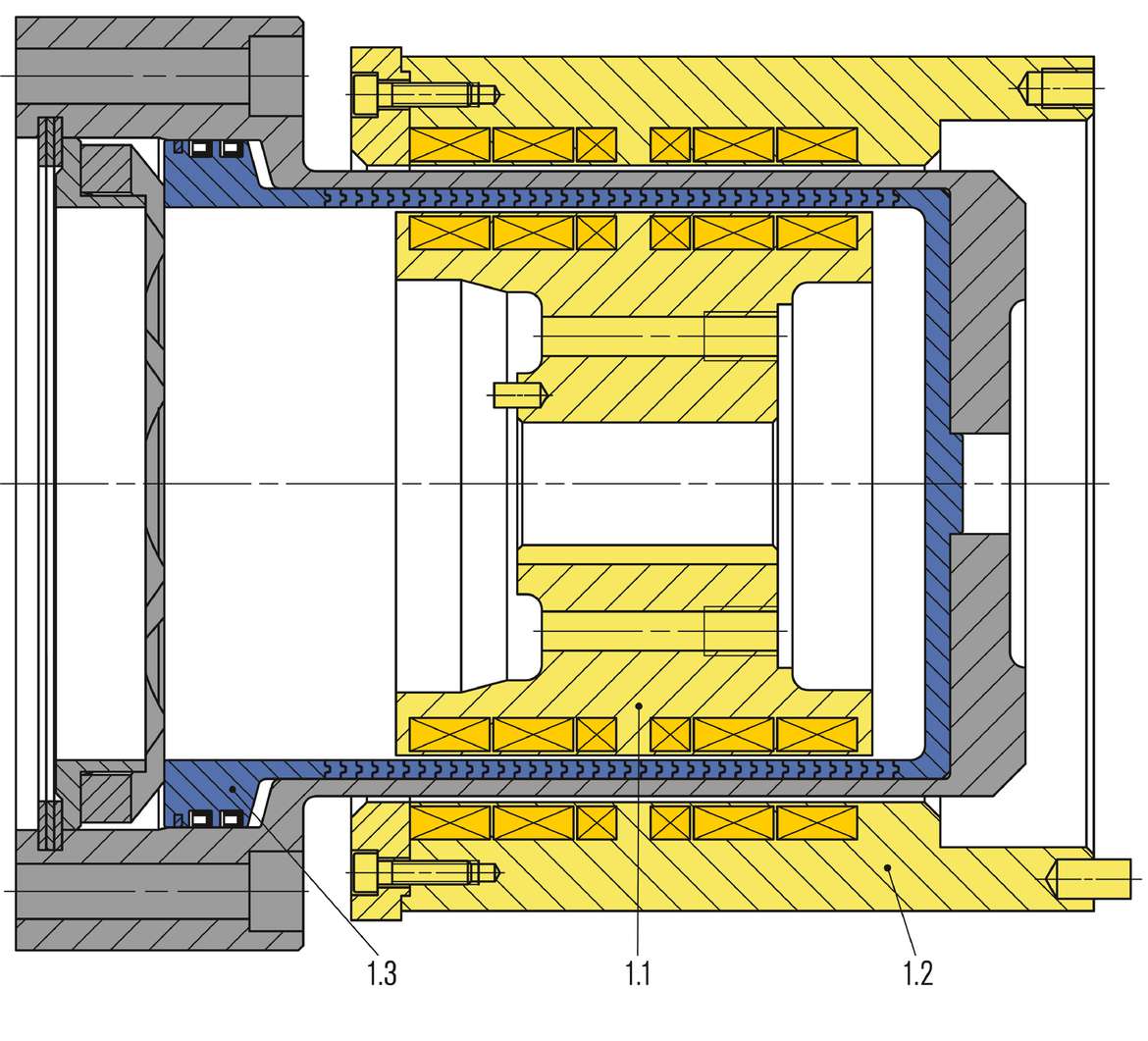

Magnetic couplings have several advantages in this type of application. On the one hand, they seal hermetically and there is no need for an external supply system. On the other hand the coupling only require minimal maintenance, and they are extremely low wearing. However, the application represents a signficant challenge from the engineering and materials point of view (e.g. the can on the coupling). The requirements profile includes high pressure, extremely high torque, high power rating and a highly flammable medium.

Initially, an NMB 22P-8R-65-ND2 was used, but it became apparent after only a few starts that a coupling with a higher power rating was needed. The sealing function did however remain intact at all times.

The reason was high torque which resulted in a break-away of the magnetic coupling between the rotating outer rotor (connection to the motor) and the synchronous inner rotor (connection of the impeller). Strong vibration and elevated temperatures were evident in the can.

An identical magnetic coupling which started gently with the aid of a frequency converter was provided as an interim solution, and it worked satisfactorily (startup profile: 0 ... 2,980 min-1 in 60 s).

EagleBurgmann Nova Magnetics designed a new magnetic coupling with a significantly higher power rating, which supports direct start and provides a more efficient and reliable solution. The coupling withstands high pressure at high rotational speeds and high torque without problems. Hastelloy (which has high strength and low electrical conductivity) was used for the can in place of 1.4571 to minimize eddy current losses and increase the efficiency and safety of the coupling. With this design, torque was increased by 63 % and eddy current losses were reduced by 35 %.

Magnetic couplings offer distinct advantages compared to other sealing systems: they are hermetically sealed, require little maintenance and help suppress vibration. For high drive power applications (>75 kW), EagleBurgmann Nova Magnetics developed a special can which continues to operate extremely efficiently at high pressure and speed (only around 2 % eddy current loses compared to 10 % on a conventional can). Lamination and electrical insulation between the layers reduce the generation of eddy currents, increasing efficiency. Engineers can provide solutions which ensure safe and cost-effective sealing and operation on large pumps.

Illustr.: Yellow parts = rotating, blue = stationary, gray = housing

Between June 2017 and March 2019 the Hengli Group constructed an integrated refining and chemical complex in the Chinese harbor town Dalian where 20 million tons of crude oil are processed every year. EagleBurgmann advised the company Hengli concerning the selection of mechanical seals and supply systems for the whole plant and supplied more than 95 % of the components in use.

In Great Britain, a shortage in natural gas supply has severe consequences: Since the country switched from coal-fired to gas-fired power stations, a gas supply shortage makes households and industrial consumers not only vulnerable to failing heating and gas stoves, but also to power outages. Companies along the value and transportation chain of natural gas are therefore especially dependent on reliable equipment.

Things get hot in rotary kilns, very hot in fact. In the production of cement, for example, the thermometer measures more than 1,000 degrees Celsius. Sealing systems from EagleBurgmann, a company of the Freudenberg Group and EKK, make sustainable contributions to environmental protection, energy efficiency and process reliability under these "fiery" high-temperature conditions.

Our modern civilization is quite literally built upon cement. Today, building materials made from cement are used in buildings, roads, bridges, dams etc. Cement production is a heat-intensive process and causes thermal expansion in duct systems. To compensate this, Indian cement producer Ramco Cement needed fabric expansion joints with a diameter of several meters for two of their plants. On the basis of a close collaboration, EagleBurgmann was able to design components that increase the efficiency of the plant in the long run.

Seals are a risk factor in the production of liquid crystals. If there is even the slightest contamination of the liquid crystals, this will later affect the image quality of the display. Read on to see which sealing solution Merck KGaA uses in paddle dryers for the production of liquid crystals.

Cruise liners have to reduce their sulfur emissions in Emission-Controlled Areas (ECAs). To accomplish this, light fuel oil is used in coastal regions - with significant consequences for the ship's fuel supply.